Fuel Injector Cleaner Tester NORDBERG CMA25AB

NORDBERG CMA25AB injector testing and cleaning unit - special diagnostic equipment for service and repair of fuel systems in service stations and service stations.

Functional

- It is designed for diagnostics and cleaning of GDI injectors installed in gasoline engines and piezo injectors used in diesel engines.

- The principle of operation of the unit is to simulate different engine operating conditions by means of pressurizing the injectors to be serviced with test fluid and a pulse signal, as well as heating the cleaning fluid and applying ultrasonic waves that remove soot and deposits.

Functions

- Nozzle resistance test

- Ultrasonic cleaning

- Uniformity / atomization test

- Tightness test

- Performance test

- Automatic test

Advantages

- Types of injectors serviced: piezo, GDI, EFI, MPI, SPFI, TBI, CFI, FSI, TSI, TFSI, etc.

- A freestanding, enlarged ultrasonic bath with temperature–controlled heating and timer ensures complete cleaning of the nozzles

- 6 nozzles can be tested or cleaned at the same time, which significantly improves work efficiency, and the ultrasonic bath bracket allows up to 12 nozzles to be installed simultaneously

- The ability to clean the injectors on the car without removing them

- A metal tray in the package, which prevents the destruction of paintwork equipment, which gets liquid flowing off when removing the nozzles

- A fine filter

- Low–resistance fuel injection testing function

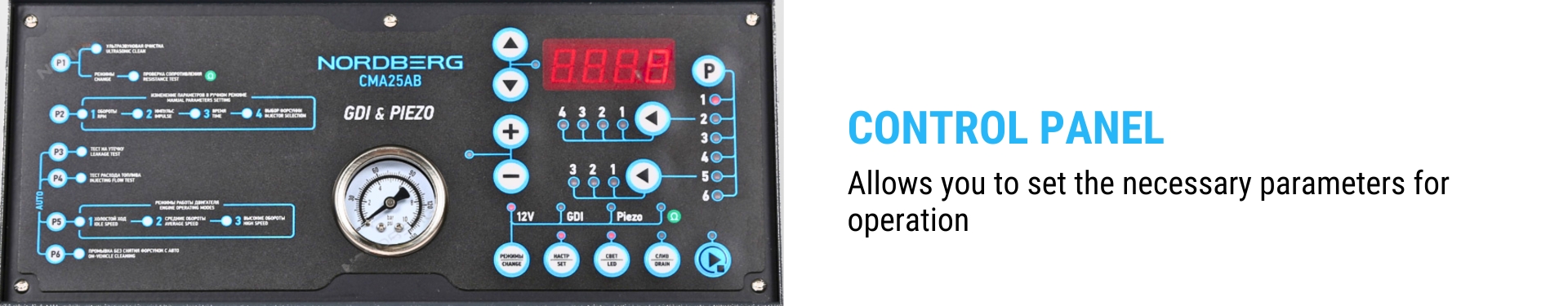

- The automatic testing mode, which is possible thanks to the built-in microcomputer, contains five different testing options that allow you to check the nozzles according to many parameters, which are given sequentially

- High-quality solenoid valves drain liquid from flasks, as opposed to using mechanical ones

- The connection wires of the nozzles are extended and color–coded

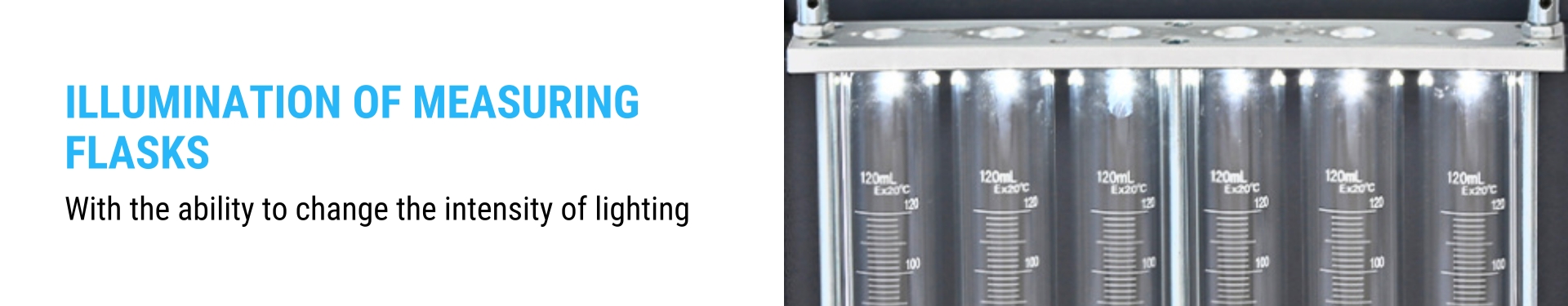

- Illumination of measuring flasks with the possibility of changing the intensity of illumination until it is completely turned off

- Convenient fuel ramp mounting system

- The microcomputer provides fuel pressure monitoring and allows you to adjust its range

- Digital display on the control panel

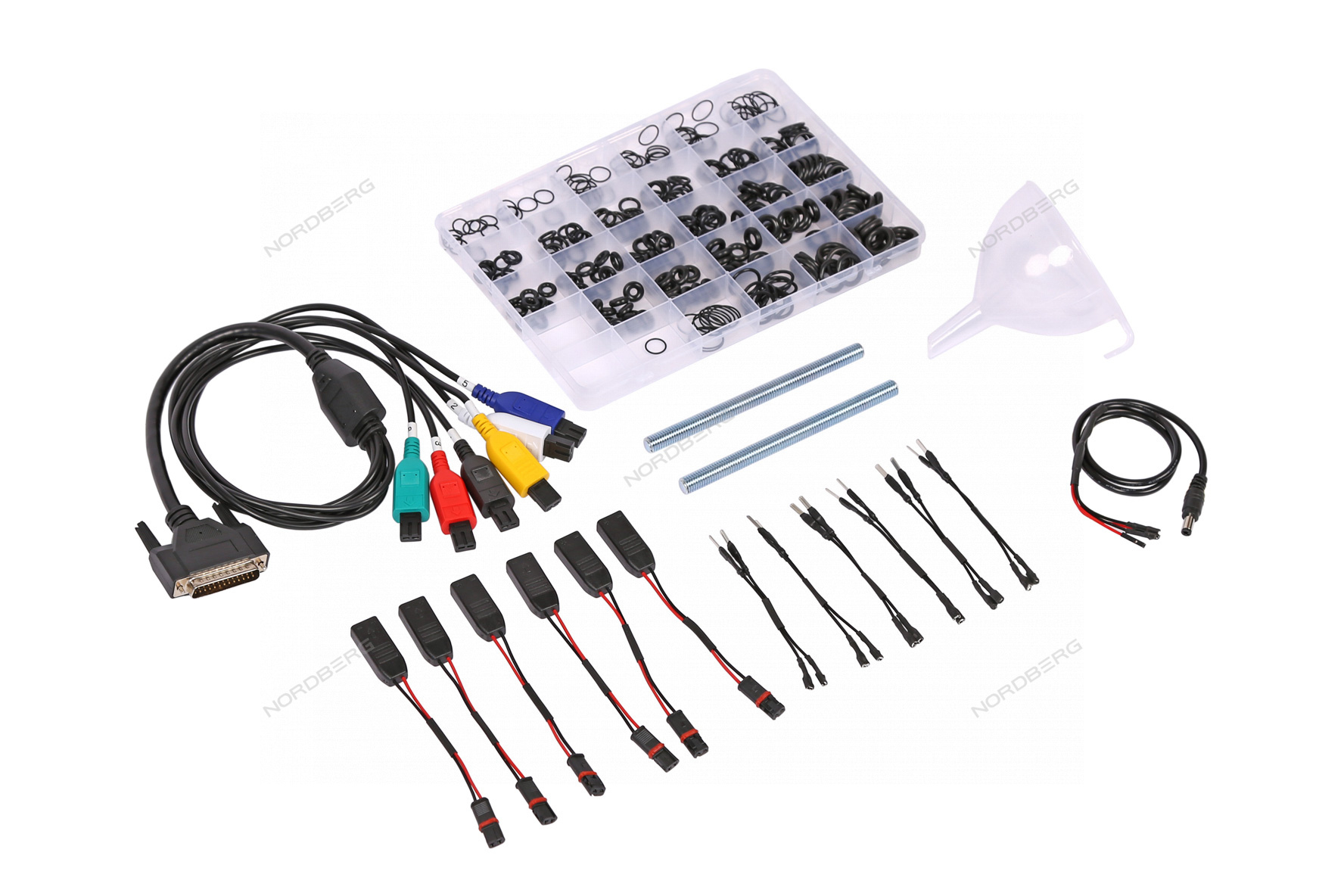

- A drawer with a large set of adapters and sets of pulse cables

- A set of O–rings for prompt on–site replacement and achieving the best sealing during testing

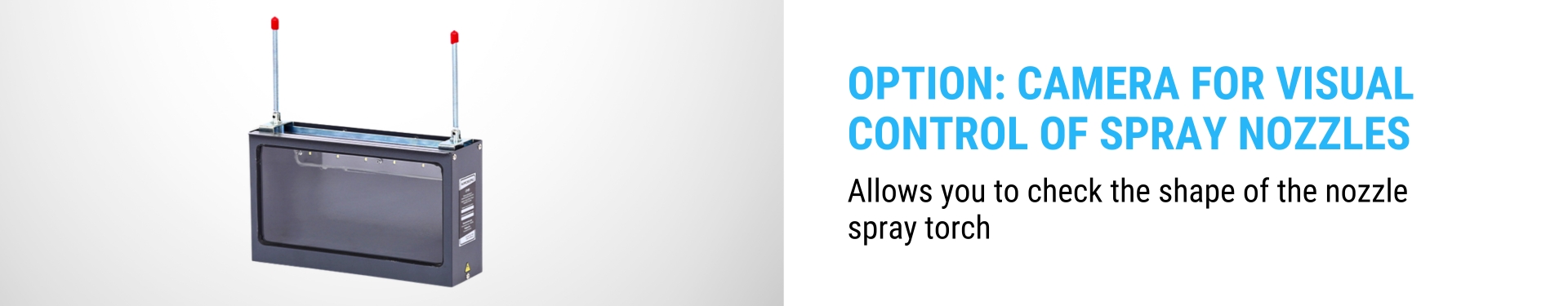

- The ability to optionally install a CMT1 visual inspection camera

- 126x60 mm filter for removing large particles of foreign matter from the coolant (optional)

Ease of use

- Intuitive interface and simple operation principle.

Contents

- Injector cleaning unit

- Side feed fuel separator

- Nut (2 pcs.)

- Auxiliary adapter (4 pcs.)

- Main adapter (4 pcs.)

- Fuel separator plug (3 pcs.)

- Nozzle gaskets (4 pcs.)

- Main impulse cables (1 set)

- Pulse signal cables

- Adapter set

- Tool set

- Metal tray

- Instruction manual

With its fast and efficient operation, the NORDBERG CMA25AB diagnostic bench will provide high performance in detecting and troubleshooting various types of fuel injectors.

Reviews

Clear filtersThere are no reviews yet.