TIG+MMA inverter welding machine for aluminum and aluminum alloys, AC/DC, 220V NORDBERG WT201

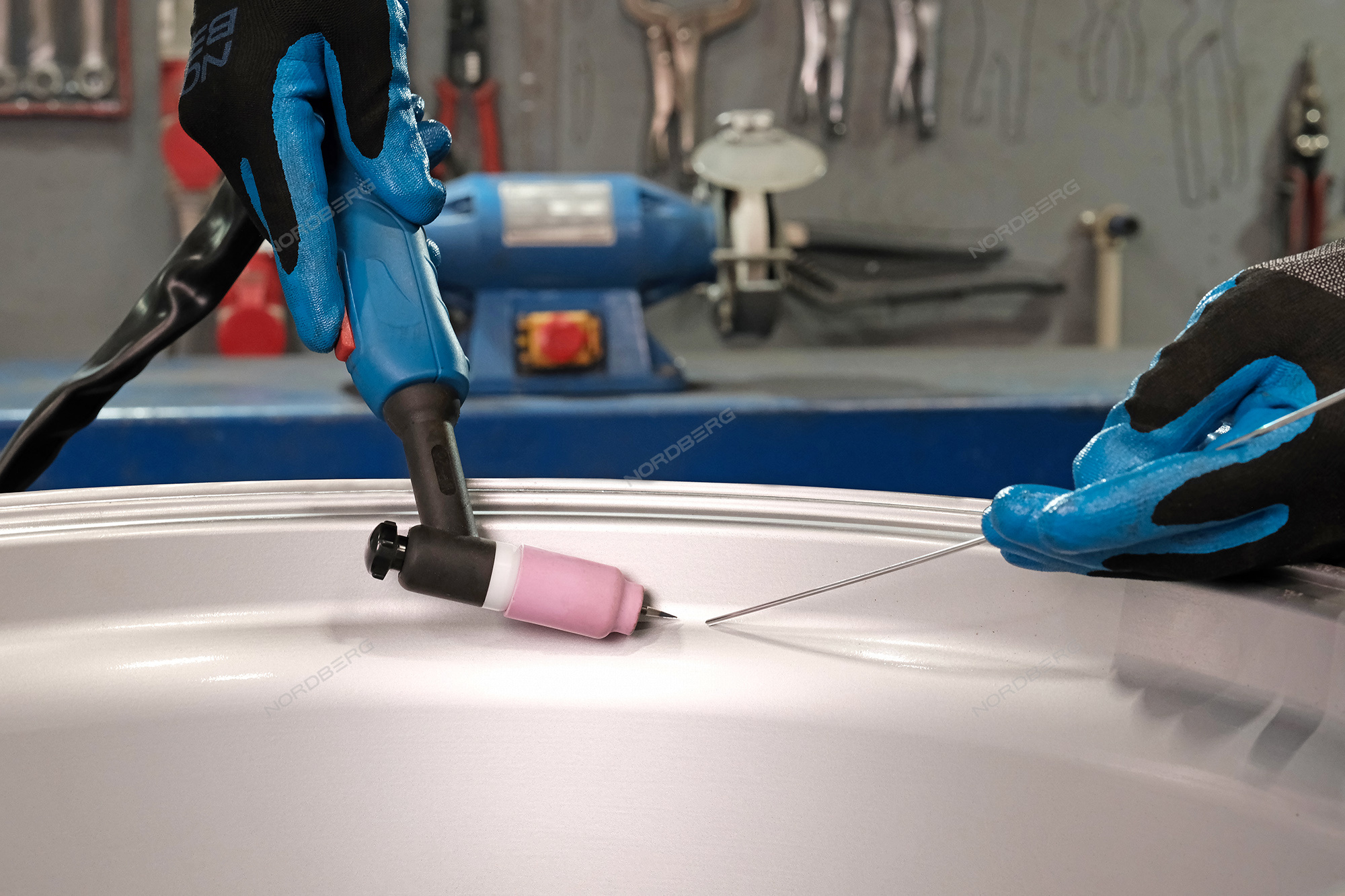

Inverter welding machine TIG+MMA for aluminum and aluminum alloys, AC/DC, 220 V NORDBERG WT201 is a universal device for electric arc and pulse-point welding of cylinder heads, crankcases, gearboxes and gearboxes, radiators, wheel rims and other body elements made of light metal alloys. It is used in car services, repair shops and at various production facilities.

Functional

The welding machine allows welding various metals such as titanium, stainless steel, aluminum alloys and alloys of other light metals, and the function of pulse welding makes it possible to work with thin metals.

The welding machine works in several modes

- TIG (Tungsten Inert Gas) is a welding process in which the use of a refractory tungsten electrode under a shielding inert gas provides precise control of the electric arc to join metals. TIG welding allows for two methods of joining metal - using the edges of the metal melted by the arc or using a special filler wire.

- MMA (Manual Metal Arc) is a welding process in which the welder uses a metal powder-coated electrode that creates an arc with a metal workpiece and a melting coating. The process allows metal parts to be joined by transferring molten material from the electrode to the joint, forming strong and stable welds.

Advantages

- Wide range of welding modes: TIG constant current, TIG constant pulse current, TIG alternating current, TIG alternating pulse current, MMA, automatic welding.

- AC/DC mode allows AC/DC operation.

- Advanced digital technology for intelligent control of the welding process.

- Arc ignition by non-contact (HF).

- For particularly demanding and decorative welding jobs, the machine has a pulse welding mode, which allows spot welding of materials of different thicknesses.

Ease of use

- The operation of the equipment is simplified and intuitive without losing control over each of the parameters of the product.

- Availability of a memory function that allows you to store 10 sets of preset parameters.

- The presence of a 5 meter pedal for remote control of the amperage, which simplifies operation.

Versatility

- The welding machine is designed for both professional and domestic use.

The NORDBERG WMI252 welding inverter has a wide range of adjustments that make working with it comfortable, high-quality and safe.

Contents

- Welding machine NORDBERG WT201

- Electrode

- Nose

- Burner nozzles - 2 pcs.

- Clamps for gas hose

- Earthing cable with clamp

- Gas hose

- Electrode holder with cable

- Pedal for remote arc ignition

- Burner

NORDBERG WT201 inverter welding machine has a wide range of adjustments that make working with it comfortable, qualitative and safe.

Reviews

Clear filtersThere are no reviews yet.