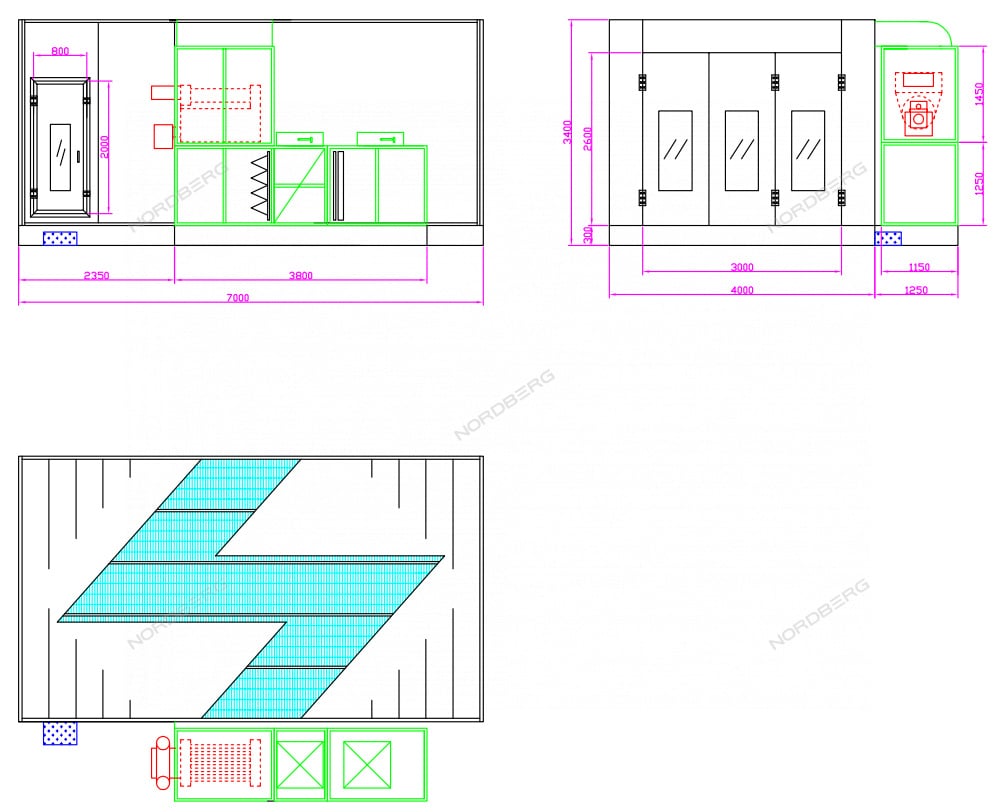

The NORDBERG spray drying booth is designed for the complete or partial painting of passenger cars. The booth consists of a cabin on a metal base with a fan group for blowing excessive air pressure inside the cabin and for ensuring a stable air flow.

The chamber operates in the following modes:

1. PAINTING

The chamber maintains a constant temperature of +20≈25⁰С depending on the paint used.

2. DRYING

The temperature in the chamber is kept constant at +60≈80⁰C depending on the paint used and the plastic parts of the car installed.

3. DRAINING

Short-term mode to remove volatile compounds and paint vapors from the chamber and to cool down after drying.

The cabin consists of sandwich panels made of thick metal and filled with polystyrene foam with additional safety margin. Side luminaires are built into the panels, corner luminaires are located along the entire length of the chamber. All luminaires are LED with reduced power consumption and are explosion-proof. Sandwich panels are reinforced with additional stiffening ribs at the ends, which significantly extends their service life and excludes situations when the panel can be squeezed out by air due to overpressure. The operator’s side door is also protected from overpressure.

The base is metal, fully lattice floor – 5 rows of lattices, wheel print load 600 kg, under the lattices there are additional metal panels for precisely calculated distribution of air flow inside the chamber. The chamber can be optionally installed on the floor or in a pit.

The two 7.5 kW motors are manufactured using the most reliable and proven technology to date, which ensures minimum noise and vibration.

This SIEMENS “squirrel wheel” design is the most reliable compared to all other solutions. The fan group can optionally be mounted on the side, rear and above the chamber (additional reinforcement is required for the upper version).

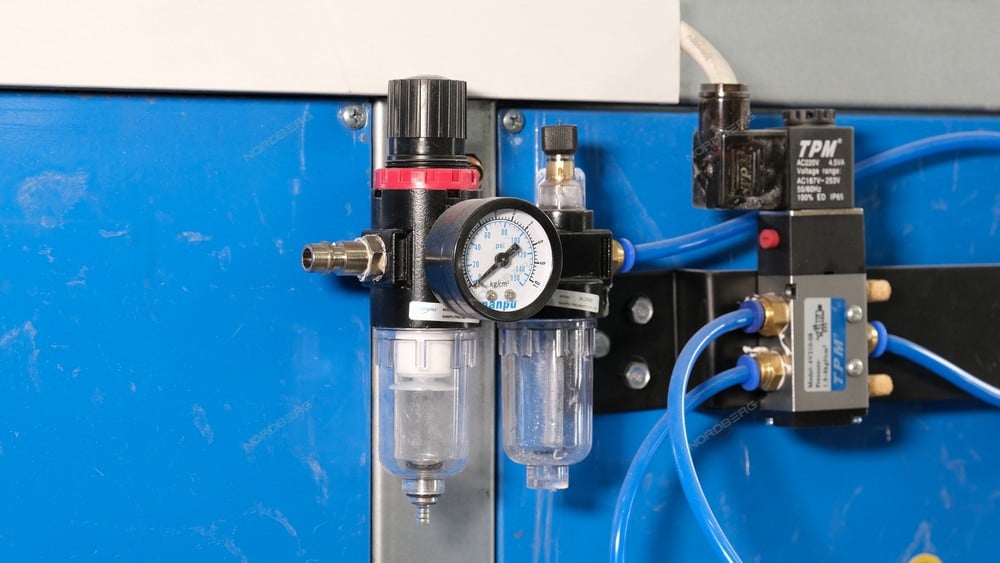

For switching between heating and drying modes, a damper (gate valve) with a pneumatic valve is used, which works much more reliably and quickly than an electric actuator, and for switching between modes it is not necessary to switch off the chamber motors.

Air heating is carried out by Italian diesel burner Riello.

The control panel is equipped with a Japanese controller Shinko or Omron. These controllers differ from cheap analogs by the fact that you can program 2 modes at once and the settings are saved for a long time, the cheap ones should be programmed weekly.

The camera is supplied with a complete set of filters necessary for full operation of the OSC.

To put the camera into operation it is necessary to purchase additionally:

- S7-1 White Sealant (Glass Glue(white)) – 5pcs

- S7-2 Polyurethane glue (Glass Glue(Polyurethane glue)) – 5pcs Ventilation boxes – their number depends on the size of the room.

- Diesel fuel tank – 1 pc

- Wires for connection of the control panel to the electric panel – the length depends on the size of the room.

- Entrance ladders (when installing the camera on the floor) – 1 set.

Any accessories available.

*Ventilation boxes are not included in the kit

Reviews

Clear filtersThere are no reviews yet.