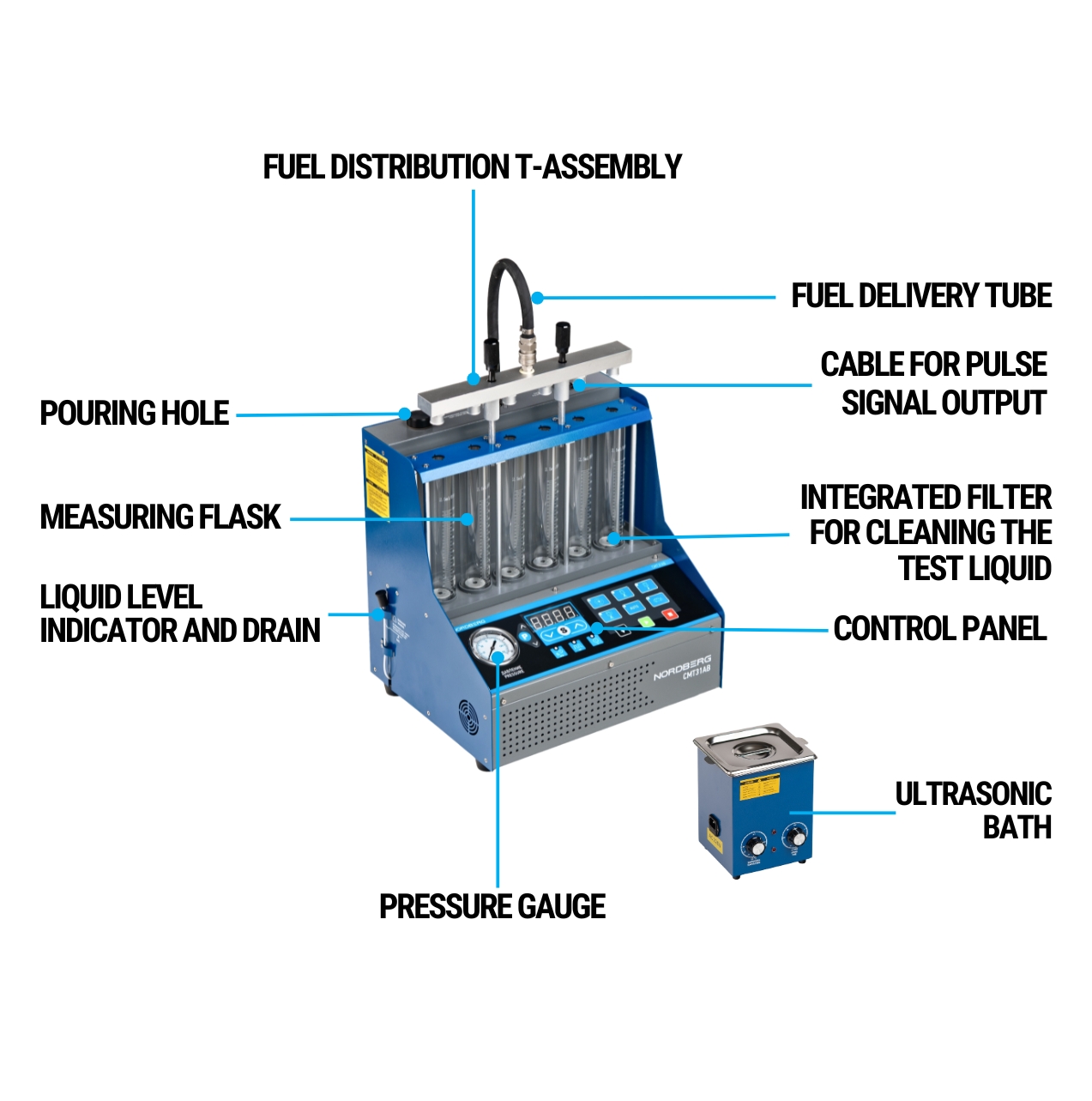

Fuel Injector Cleaner Machine NORDBERG CMT31AB

The NORDBERG CMT31AB injector testing and cleaning unit is a special diagnostic equipment for servicing injector systems of gasoline engines in car service centers or service stations.

Functional

- The operating principle of the unit is to simulate different engine operating conditions by means of pressurizing the injectors to be serviced with test fluid and a pulse signal, as well as heating the cleaning fluid and applying ultrasonic waves that remove carbon and deposits.

- The NORDBERG CMT31AB creates optimal conditions for injector performance testing and cleaning to improve engine performance, reduce fuel consumption and extend the life of fuel injectors.

Functions

- Ultrasonic cleaning

- Uniformity / atomization test

- Leakage test

- Injection flow test

- Automatic test

- On-vehicle cleaning function

Advantsges

- Types of injectors serviced: SPI, MPI, SFI, PFI

- Freestanding ultrasonic bath (length/depth 13,5x6,5 cm) with heating and timer provides full cleaning of 6 injectors, bracket for eight injectors

- Automated drainage of test fluid

- The automatic test mode, possible thanks to the built-in microcomputer, contains six different test options to test the injectors on many parameters, which are carried out sequentially

- A control panel with buttons with clear symbols and a digital display provide easy and accessible operation of the unit

- Microcomputer provides control of fuel pressure and allows to adjust its range

- Compact and mobile design

- Set of adapters and sealing rings included

Contents

- Injector cleaning kit

- Fuel distributor kit, including adapter 2 (D13.5)

- Adapter 1 for injector with top fuel feed (D10.5) (6 pcs)

- Pulse signal cable #1 for one injector (6 pcs)

- Support adapter with wide edge (D11) (6 pcs)

- Ultrasonic reservoir

- Adapter with large thread for top-feed fuel injector (M12X1.75) (6 pcs)

- Adapter with Swiss thread for top-feed injector fuel (M10x1.0) (6 pcs)

- Impulse signal cable No. 2 for one injector (6 pcs)

- Support adapter with wide edge (D14) (6 pcs)

- Plug (G1/4") (5 pcs)

- Adjusting bolt (2 pcs)

- Funnel

- Sealing rings NBR (1 set)

- Case

- Nut with lock washer (2 pcs)

- Adjusting bolt (2 pcs)

- Sprayer

- Power cable

Reviews

Clear filtersThere are no reviews yet.