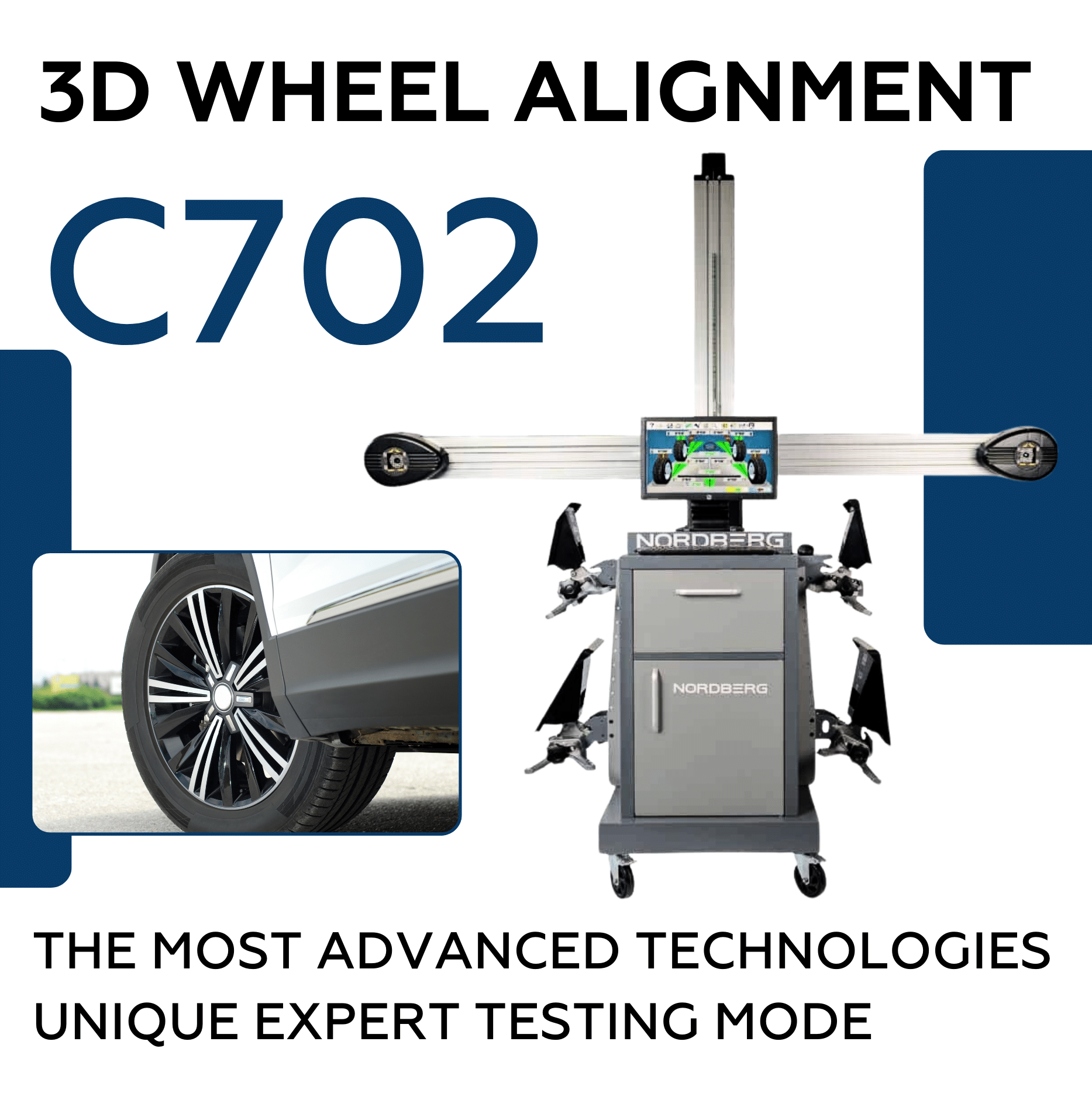

Wheel alignment 3D, 2 cameras NORDBERG C702 with thin post and camera beam at the front

Wheel aligner NORDBERG C702 3D has a stable, accurate, low-cost and easy -maintain wheel alignment system, designed for business expansion and high-performance requirements.

C702 has outstanding and unique features, such as friendly operation interface, fast and stable search function, excellent camera and optical system, perfect additional measurement, etc.; It adopts the most advanced technology and has a unique expert testing mode, which can help workshop engineers to carry out professional and very fast alignment work.

Specializing in 3D wheel alignment, the C702 is more reliable over a whole, more cost-effective, save time and work efficiently, suitable for automaker workshops, independent workshops or tire service workshops for mass wheel alignment at a reasonable cost.

Advantages

- High-resolution digital two cameras with wide-angle views and color indicators.

- Self-centering wheel clamps with quick adjustment (11"-22" grip) and corrosion protection.

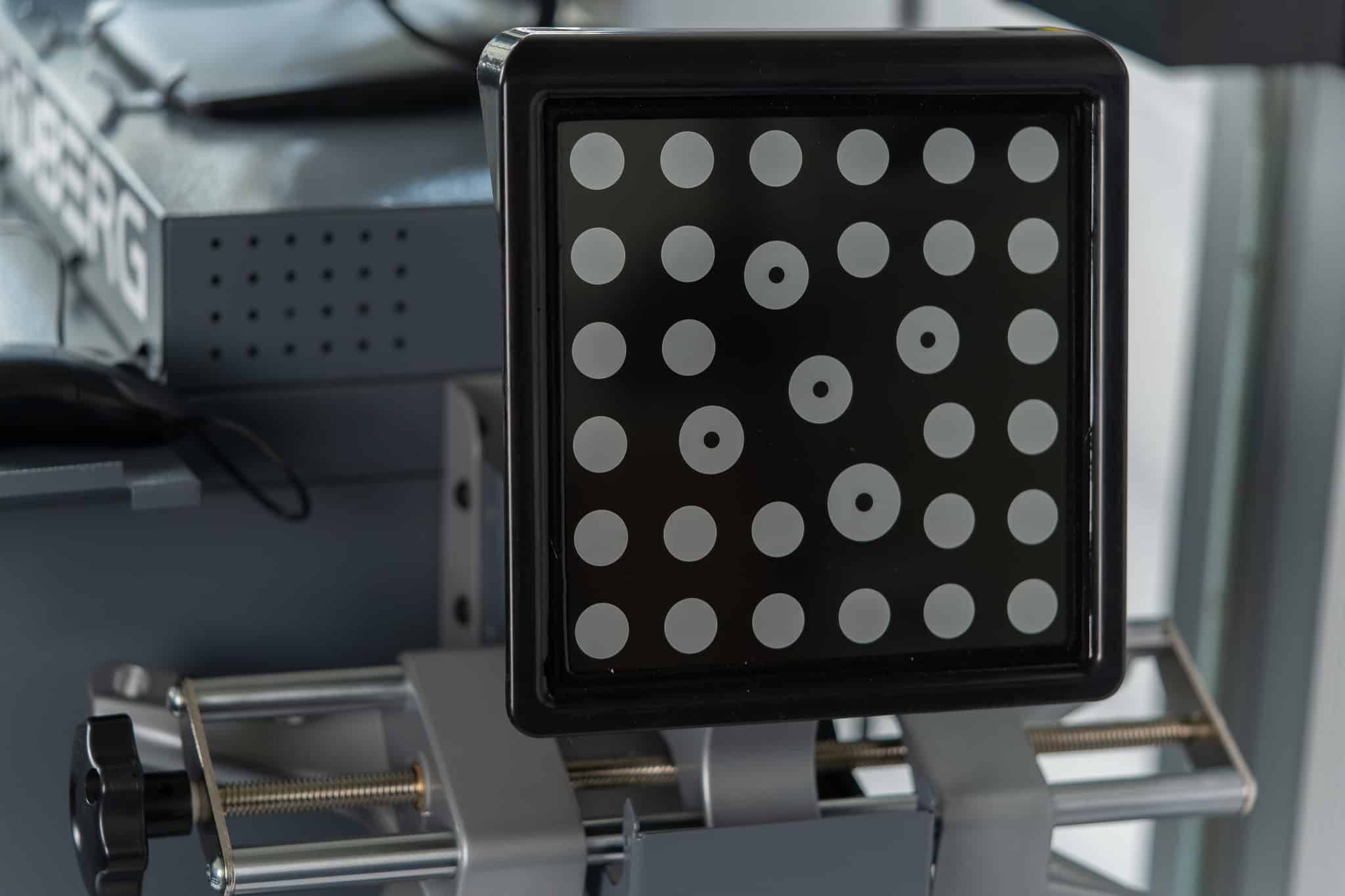

- Impact-resistant plastic target reflectors with wireless connectivity.

- Software based on Windows OS: user-friendly, operator prompts, data animation, and visualization.

- Standard accessories included:

- 2 swivel plates

- 2 anti-roll blocks

- Alignment kit for swivel plates

- Steering wheel lock

- Brake pedal lock

- Electromechanical lift/lower drive for an extended range of visible heights (100-1700 mm) when performing measurements on a lift, automatically tracking the height of the targets.

- Convenient mobile stand with equipment mounts.

- High-quality aluminum column and beam profile resistant to temperature deformation.

Software, measurements, interface

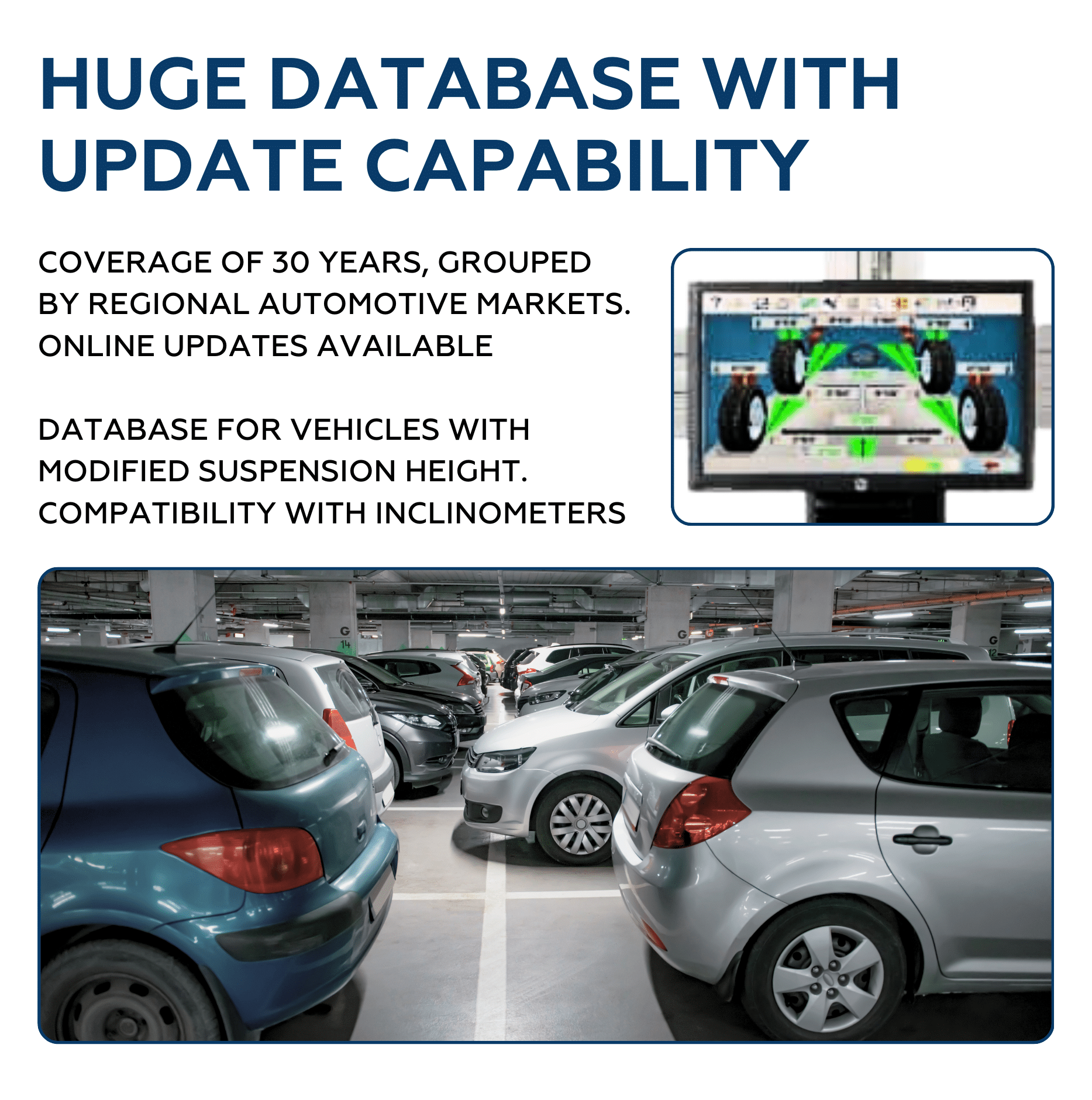

- Huge database with update capability

- Coverage of 30 years, grouped by regional automotive markets. Online updates available.

- Database for vehicles with modified suspension height. Compatibility with inclinometers.

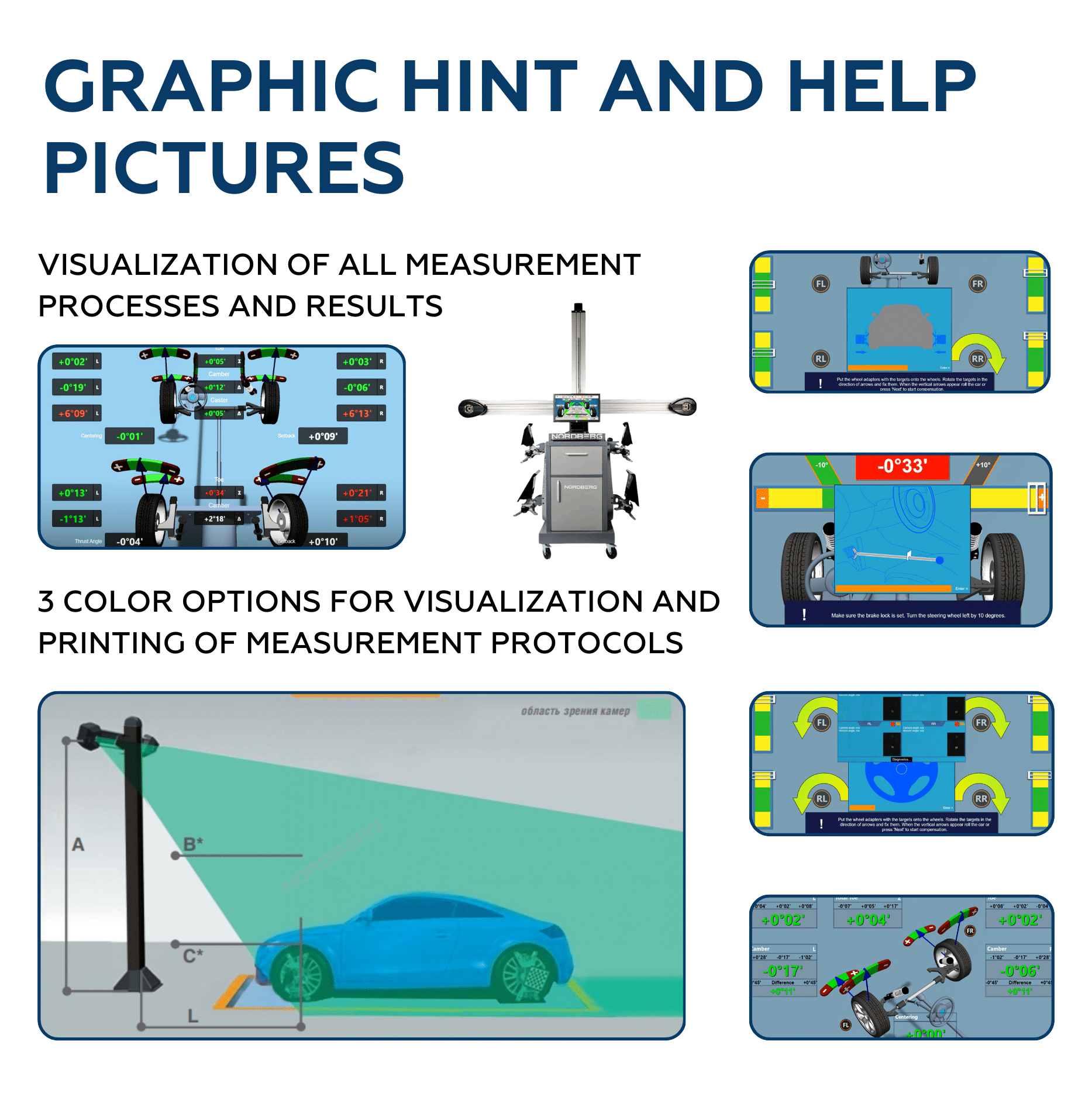

- Intelligent interface

- Assistance with adjustments.

- Visualization of all measurement processes and results. Choice of measurement units. Bright color indication of processes. Self-diagnostic programs.

- 3 color options for visualization and printing of measurement protocols.

- Operator's workstation

- Integrated system for customer vehicle management. Ability to input parameters of new vehicles into the database. Storage and output of calibration history.

- Fast measurements, accurate results, efficient adjustment

- Measurement cycle takes only about 3 minutes: simply place the vehicle, select the model in the database, set the targets, and perform forward-backward "rolling."

Performed measurements include:

- Total and individual toe-in (convergence) and camber (front and rear wheels).

- Caster (longitudinal tilt angle of the pivot axis).

- Kingpin inclination (crosswise tilt angle of the pivot axis).

- Camber with zero toe-in (convergence).

- Caster and camber during vehicle lifting.

- Toe-out angle, front and rear axle offset angles.

- Vehicle geometry: wheelbase magnitude and difference, track width and track width difference, control diagonals.

- Diagnosis of steering system asymmetry when turning the front wheels using the Ackerman angle.

Scrub radius and caster trail.

Technical Specification

| Specification | Item | Accuracy | Range | Total Range |

| Front Wheel | Camber | ±0.02° | ±10° | ±10° |

| Caster Angle | ±0.05° | ±10° | ±10° | |

| Kingpin Caster Angle | ±0.02° | ±20° | ±20° | |

| Toe | ±0.02° | ±2.4° | ±4.8° | |

| Rear Wheel | Rear Axle Offset | ±0.02° | ±2° | ±4° |

| Maximum steering Angle | ±0.08° | ±25° | ±45° | |

| Thrust-angle | ±0.02° | ±2° | ±4° | |

| Track Width Difference | ±0.03° | ±2° | ±8° | |

| Front Set Back | ±0.02° | ±2° | ±4° | |

| Rear Set Back | ±0.02° | ±2° | ±4° | |

| Track Width | ±0.64cm(0.25cm) | <265cm(105in) | <265cm(105in) | |

| Wheel Base | ±0.64cm(0.25cm) | <533cm(210in) | <533cm(210in) |

Reviews

Clear filtersThere are no reviews yet.